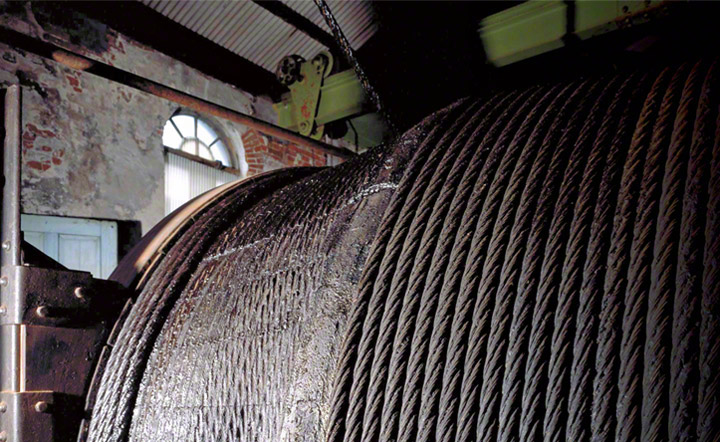

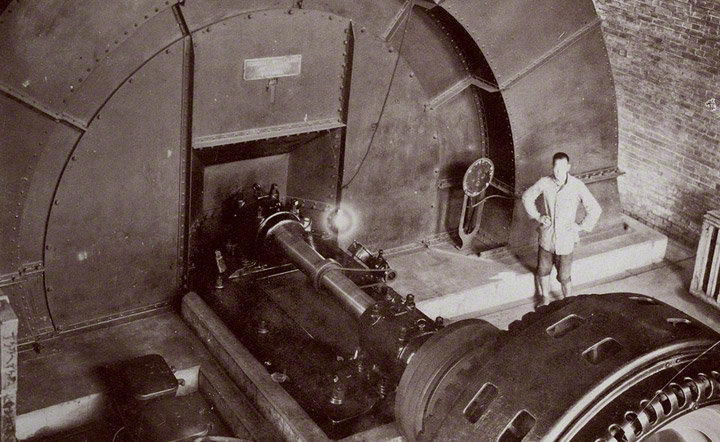

Miike Coal Mine was Japan's second coal mine to be modernized after Takashima Coal Mine. Miike is renowned for its high quality bituminous coal, but production was a challenge due to excessive groundwater. A massive investment in modern machinery was required to achieve mass production. The modernization of Miike was accomplished by the Mitsui group of companies that had the financial capacity to import the largest and most up-to-date Western equipment - which eventually gave way to the production of large-scale mining machinery at a factory of its own. British mining equipment was introduced together with a new adit system for centralized drainage. It was the most advanced Western pumping and winding technology available in Europe at that time.

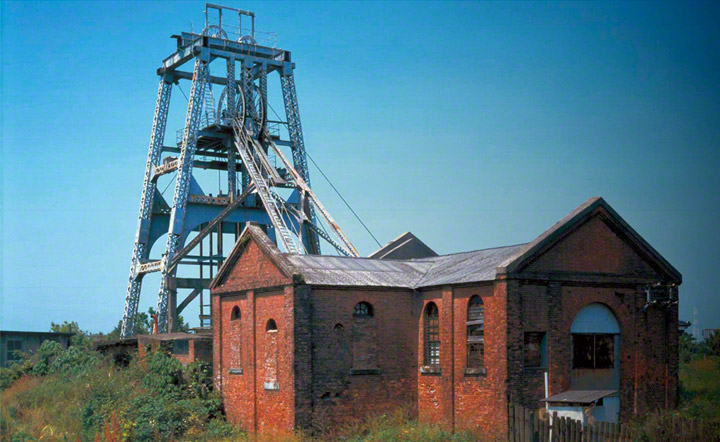

Miyanohara and Manda Pits were the main pits of Miike Colliery in the early twentieth century. Miike Coal Mine's red brick shaft-head buildings, and their attendant steel head frames and sheave wheels, have dominated the local landscape for over a century. They exemplify the transplant from Britain to Japan of the most advanced Western pumping and winding technology available in Europe at that time. The mines and port were linked by an early example of an electric powered coal railway helping to facilitate the mass distribution necessary in the modernized export coal field. Miike Port served Miike Mine as the largest coal export port built in Japan. Its technology, scale and layout were exceptional, and its enduring design and continued use are testimony to the forward looking Mitsui.

The development of a mass distribution system required railways and electricity, and a suitable port critical for the export of large volumes of coal. Coal production and distribution transformed the rural Japanese landscape into a modern Western style coal mining cultural landscape.

| Designation: | National historic site (Miyanohara Pit, Manda Pit, Miike Coal Railway) Structure of Landscape Importance (Miike Coal Railway) National important cultural property (Miyanohara Pit, Manda Pit) |

|---|---|

| Address: | 200-2 Hasuike, Haramanda, Arao city, Kumamoto |

| Tel: | 0968-57-9155 (Manda Pit Station) |

| Opening time : | 9:30-17:00 (Manda Pit Station) |

| Close date : | Monday, Dec 29- Jan 3 (Manda Pit Station) |

Miike Port

Miike Port Misumi West Port

Misumi West Port